Product Description

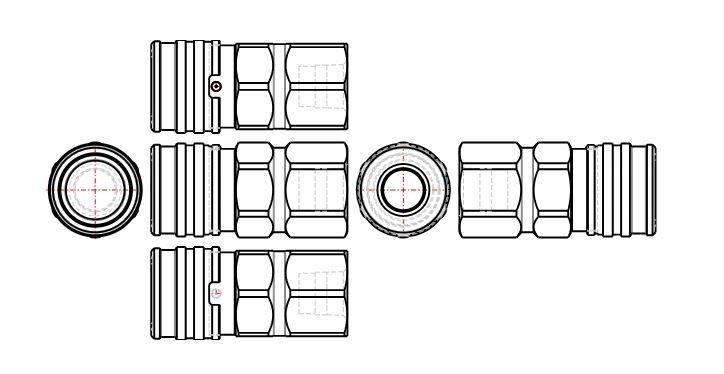

Pioneer FEM Series Non-Spill Hydraulic Coupler | FEM-501-8FP

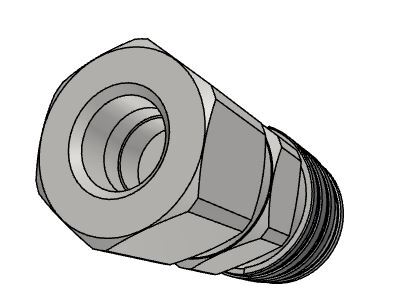

FEM Series couplings meet or exceed ISO 16028 design and performance requirements. The flush valves eliminate spillage and air inclusion when connecting and disconnecting. Coupler and nipple bodies have a modular design with increased flexibility for end port options. FEC nipples provide a connect-under-pressure option for trapped residual pressure.

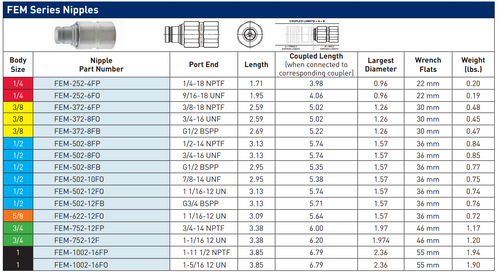

FEM Series Nipples (hydraulic) up to 5000 psi, connect with FEM Series Couplers. All FEM Series parts meet or exceed design and performance requirements of Hydraulic Tool Manufacturer's Association (HTMA - ISO 16028) standards.

Parker's FEM Series quick connect fittings are double shut off, non-spill, flat face quick couplings designed to minimize spillage and air inclusion when connecting or disconnecting and are interchangeable with other products complying with HTMA - ISO 16028.

FEC nipples are designed to connect under pressure, in situations where fluid lines contain residual pressure caused by thermal expansion. The FEC Series connect-under-pressure rating ranges from 1500-3000 psi dependent on body size.

Features:

- Flush, non-spill valving

- Global interchangeability with other ISO 16028 compliant couplings

- Hardened nipple bodies

- Sleeve-Lok design standard

- Connect-under-pressure FEC nipple option

- Protective zinc nickel plating

- Non-spill, flat face valves minimize fluid loss when disconnecting, to reduce environmental contamination and avoid safety hazards caused by spillage.

- Flat face valves minimize the amount of air that can enter the system when connecting fluid lines, thus preventing accelerated wear of the system's components.

- Male bulkhead fitting ends for panel or plate mounting options

Specifications:

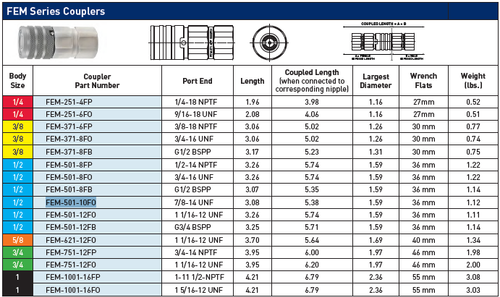

- Body Size: 1/2"

- Nipple Part Number: FEM-501-8FP

- Port End: 1/2-14 NPTF

- Length: 3.26"

- Coupled Length: 5.74"

- Largest Diameter: 1.59"

- Wrench Flats: 36mm

- Weight(lbs): 1.22

- Coupling Half: Female Coupler

- Specifications Met: ISO 16028, ISO 16028, HTMA

- Maximum Operating Pressure: 5000

- Maximum Operating Temperature: 250 °F, 110 °C

- Valve Type: Non-spill

- Application: Hydraulics, n/a, non-spill

- Minimum Operating Temperature: -40 °F, -40 °C

- Connection Type: Female NPSF

- Product Type: Push to Connect, Quick coupling

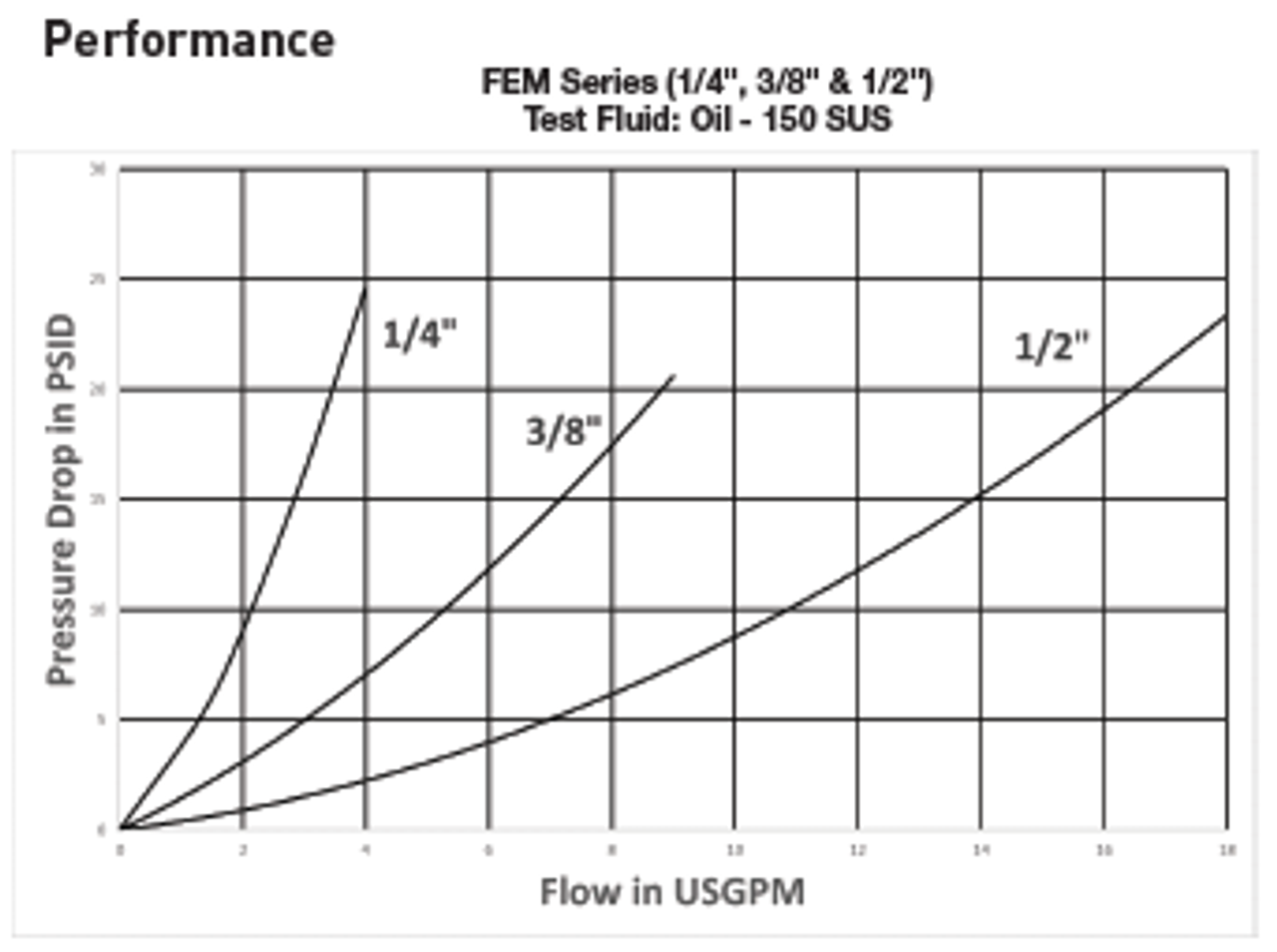

- Flow Rate: 12 gal/min, 55 L/min

- Body Material: Steel

- Plating Type: Zinc Nickel, Zink Nickel

- Seal Material: Polyurethane/Nitrile, NBR

Technical Characteristics:

- FEM Sizes: 1/4” – 1”

- FEC (Connect Under Pressure) Sizes: 1/2", 5/8", 3/4"

- Materials: Steel

- Port Ends: Female NPSF, Female ORB, Male Bulkhead Flare, Male Bulkhead Face Seal

- Seal Options: Nitrile/Polyurethane, EPR, Fluorocarbon

Markets:

- Industrial

- Construction

- Utility

- Agriculture

Applications include:

- Skid loader attachments

- Hydraulic tools

- Construction equipment attachments

- Industrial hydraulic lines

- Agricultural implements

- Coolant fill and drain lines - Contact QCD for a brass, FEM style drain port nipple that is recommended for use by the Technology and Maintenance Council of the American Trucking Association, TMC Recommended Practice 353

Materials of Construction:

- Body: Steel

- Finish: 1/4”, 5/8” to 1” Zinc with clear trivalent chromate 3/8” & 1/2” Zinc Nickel

- Valve: Flush face valving

- Seal: Polyurethane and Nitrile

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.

- This document and other information from Parker-Hannifin Corporation, its subsidiaries and authorized distributors provide product or system options for further investigation by users having technical expertise.

- The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance, maintenance, safety and warning requirements of the application are met. The user must analyze all aspects of the application, follow applicable industry standards, and follow the information concerning the product in the current product catalog and in any other materials provided from Parker or its subsidiaries or authorized distributors.

- To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specifications provided by the user, the user is responsible for determining that such data and specifications are suitable and sufficient for all applications and reasonably foreseeable uses of the components or systems.

US Dollars

US Dollars

Canadian Dollar

Canadian Dollar

Australian Dollar

Australian Dollar

Euro

Euro